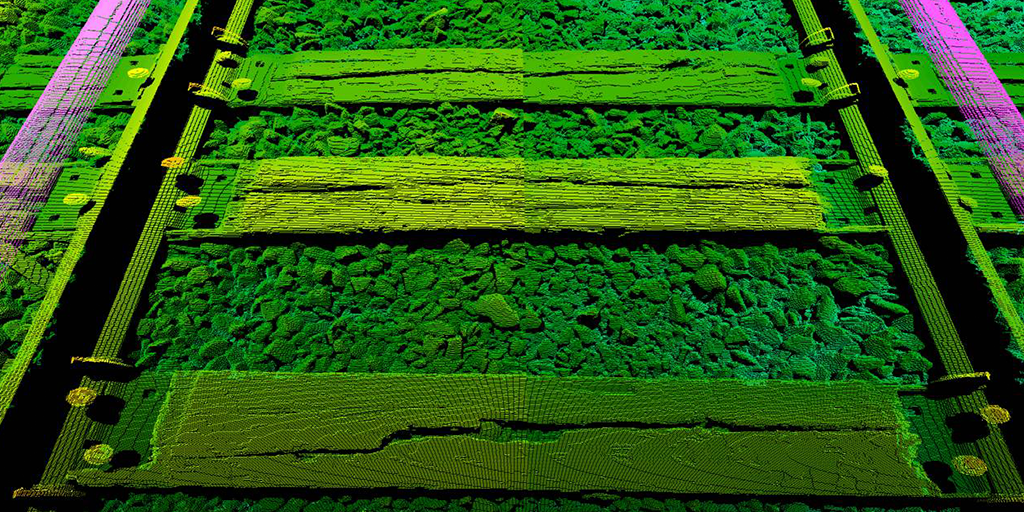

Wood Tie Grading

Wood tie fails are often due to decay and deterioration that isn’t visible from the surface. Aurora Xi combines both surface and internal images to find hollow or damaged areas in the tie that inspectors might miss. It then assigns a grade to each tie so you can forecast a ties remaining life accordingly.

Data Management

Aurora Xi provides easy-to-understand reports tailored to your railway’s specific needs. Tie grade reports make it easy to forecast the life of your ties and plan replacement programs accordingly. Detailed compliance reports allow you to confirm that you have at least the minimum number of effective wood ties in a segment, uncover rail joints with defective crossties.

Optimized Tie Set Out (TSO)

Utilizing Aurora inspection data as well as the railroad’s tie replacement logic to identify exactly which ties need to be replaced, the TSO system can then optimize the plan for tie distribution, allowing you to know exactly where to set out ties and eliminate the need for someone to walk the track and physically mark where to set out ties ahead of the tie distribution team.

The software allows the user to know where to set out ties and how many are required for each drop as they travel along the track. The result is ties that are much closer to where they will be installed, allowing for increased productivity for tie replacement teams as they will spend less time moving ties around to the appropriate install location.