Double undercutting productivity for less time on the mainline

Loram’s UC1200 undercutter cleaner is the industry’s most advanced, most productive and highest-capacity, self-contained system for any undercutting program. The UC1200 features innovative, twin rotary undercutting technology and dual material discharge for handling and cleaning up to 1,200 m³ of excavated ballast per hour at enhanced operational speeds.

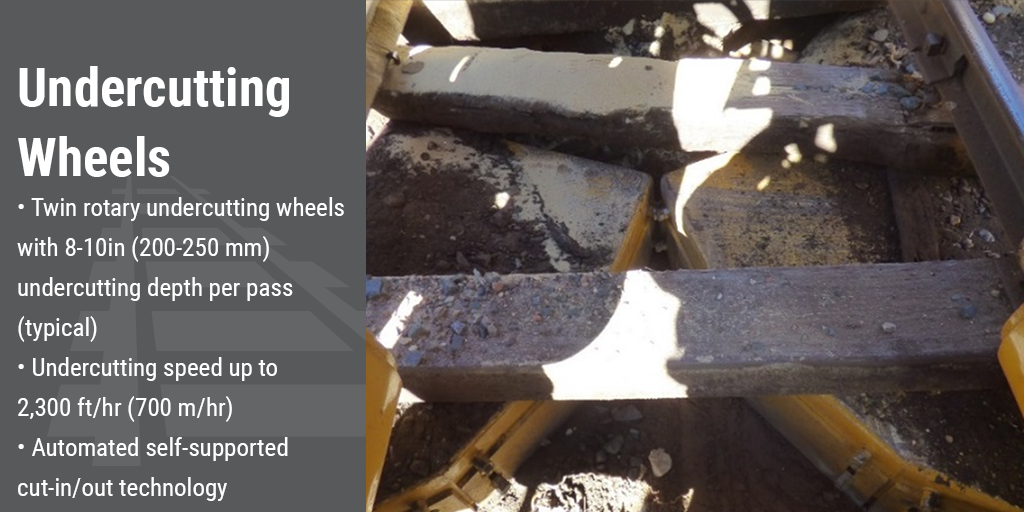

Loram’s patented, twin undercutter wheels allow the UC1200 to quickly cut in and cut out. Unlike chain undercutters, the UC1200 doesn’t need any auxiliary equipment to remove ties or ballast to cut in. The UC1200’s wheels can undercut a track near adjacent tracks that have 14-foot or larger track centers without disturbing the adjacent track. With the versatility of the Loram undercutter wheels, tracks with 8- to 10-foot ties can be undercut.

A comprehensive and versatile solution to ballast maintenance, Loram’s UC1200 integrates industry-leading undercutting capabilities, along with the ability to perform either ballast cleaning or waste-only ballast removal. A 7 ×20-foot double-deck separator screen, with exclusive elliptical throw agitation and variable screen leveling, separates the reusable ballast from the dirt, mud and fines. The UC1200 then restores reclaimed ballast to the top of the ties, and spoils are placed onto a swing conveyor that can discharge the material up to 35 feet from track center. The conveyor can also transfer spoils into a material handling or dump car.