Collect precise rail grinding data

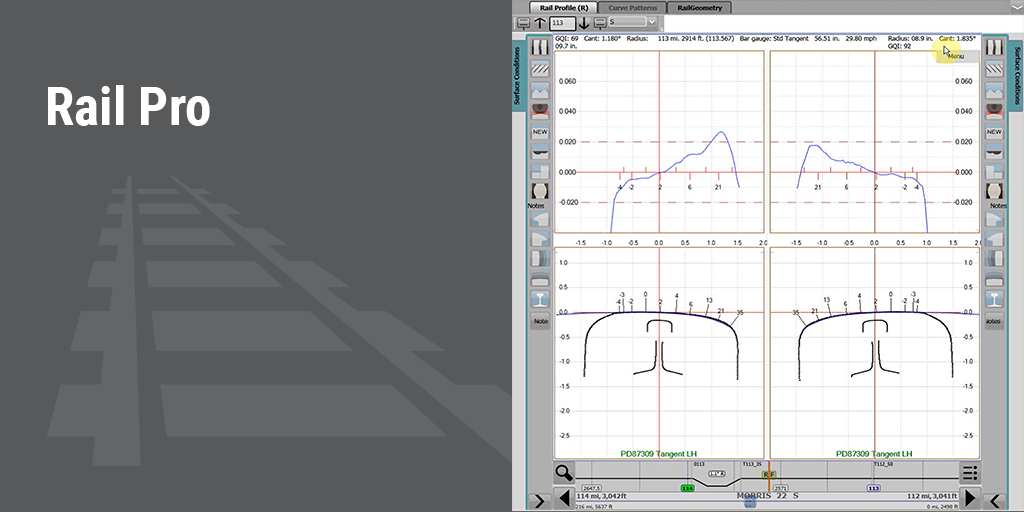

The Loram Rail Inspection Vehicle (RIV) offers an efficient and cost-effective data collection technology solution for accurate rail profiling and grind planning. An experienced Loram technician conducts the profile and surface inspections using the hi-rail vehicle-based measurement system to automatically determine optimal grind angles, passes, patterns, and rail grinder speeds to ensure the proper rail profile is achieved for both main line and specialty track work.

The RIV provides an efficient and accurate means for collecting rail profile, rail wear, gauge, and cant data for managing a rail grinding program. Collected data is mapped to exact track locations to positively match the plan and apply the rail grinder. The RIV is equipped with a rail profile measurement system and reporting package to assess rail quality assurance and planning needs. This package of several integrated components is a proven system in use throughout North America and other locations worldwide.