Remote Monitoring

Data is more important than ever. With Loram’s remote monitoring systems and analytical services, railroads can receive the full financial benefits of their friction management program.

Data collection. Data reporting. Data analysis.

Loram’s remote monitoring system continuously collects data and turns it into understandable, usable, and manageable information. This streamlined information allows railroads and maintenance technicians to:

- Maximise uptime

- Prevent both minor and major issues before they occur

- Increase unit reliability

- Improve the effective utilisation of friction management systems

- Coordinate service visits

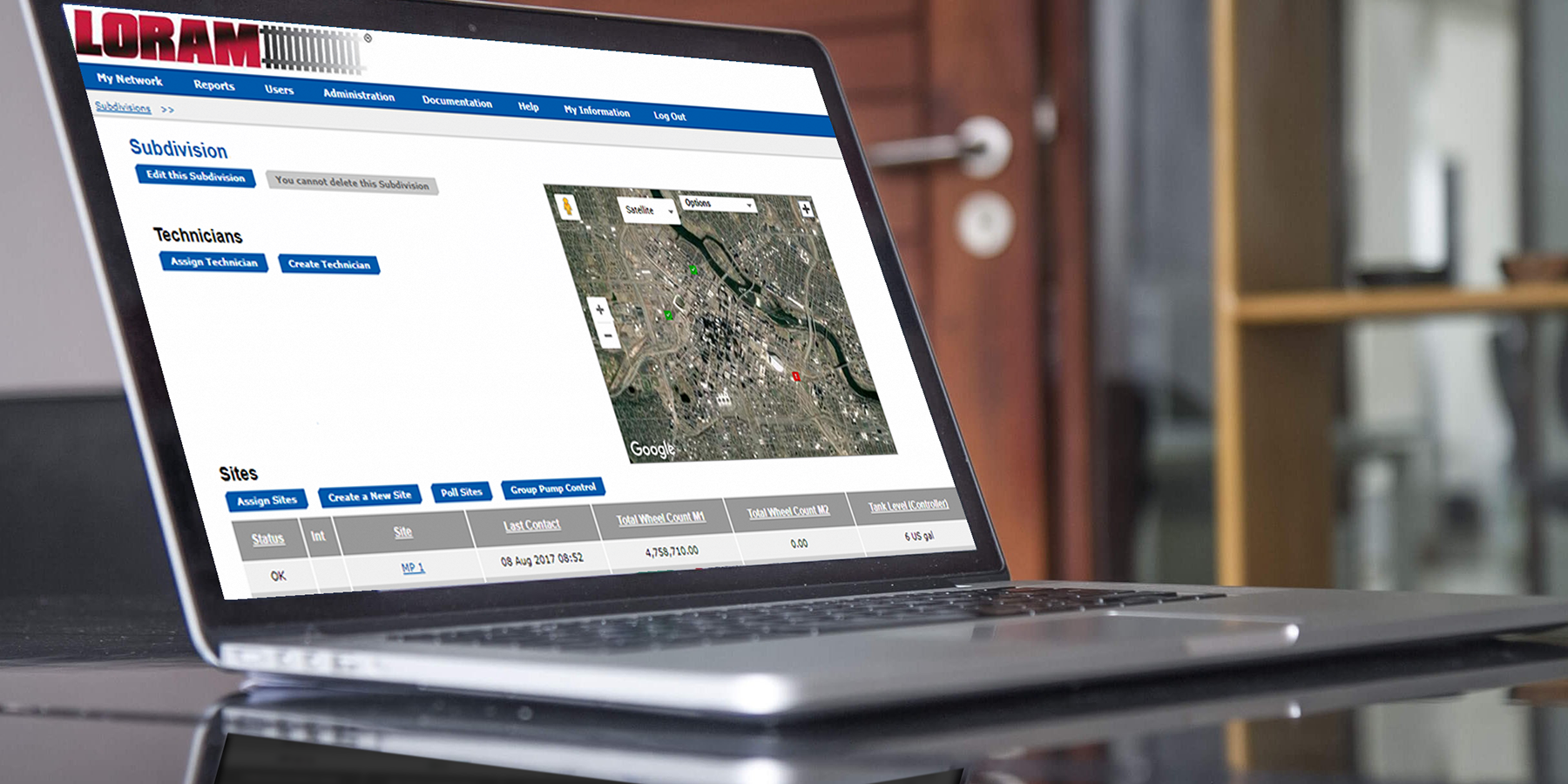

Loram remote monitoring units are compatible with any industry standard friction management system. Loram provides a web accessible portal to allow railroads and maintenance technicians to see data on an entire population of units or units in specific territories. Railroads can control permission levels of their maintenance technicians, so the maintainers can view data for only the specific units for which they are responsible.

Loram’s web portal also provides understandable daily, weekly, and monthly reports to railroad leadership and other necessary personnel. Loram’s remote monitoring system compiles the friction management system’s data continuously and train specific data during each event.

System specific information includes:

- Solar power voltage

- Power source voltage

- Door status

- Friction modifier level

- Readings from other optional sensors

Train information captured includes:

- Direction of travel

- Axle count

- Amount of material applied

Trust Loram’s remote monitoring and analytics services to keep you fully informed about the friction management program and improve the effective utilization of friction management systems.