A better, faster and safer way to handle long rail

Since the introduction of continuously-welded rail, delivering rail from the welding plant to the worksite and picking up used rail from trackside, has proven to be a manual labor intensive and unsafe process.

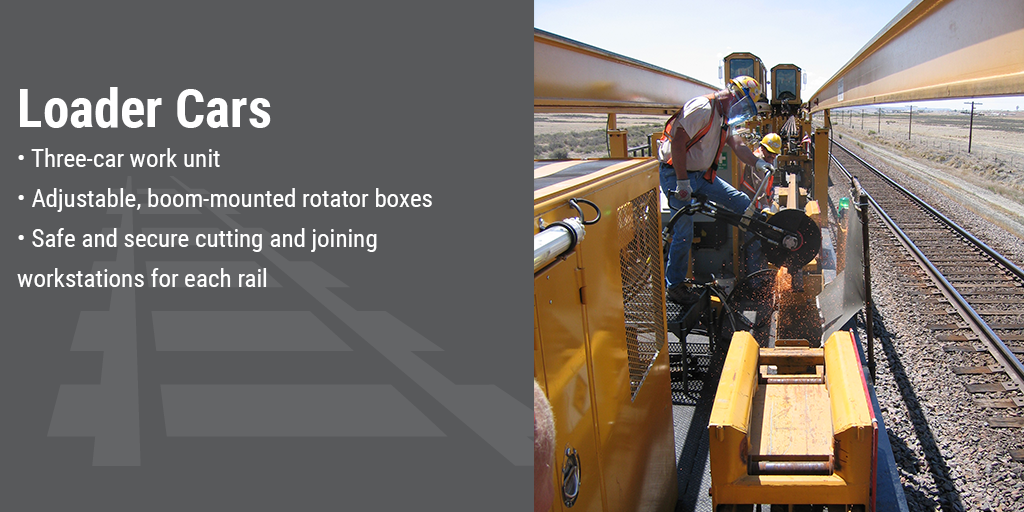

Loram’s Raptor rail train is a long rail pick-up, handling and delivery system that manages cradle-to-grave rail logistics. The Raptor consists of twin, independent rail loading machines with telescoping booms and a 3-car work unit with rail joining workstations, coupled with high-capacity rail transport trains.

The Raptor Rail Handling System improves safety by reducing manual handling of rail and keeping people out of harm’s way. The twin-independent rail-loading machine booms eliminate the need for a ground crew as well as the need to guide the rail through the transport train during loading. The Raptor also has an ergonomically designed cutting and joining station that locks the rail in place when human interaction is required and provides superior access to power tools and supplies, which greatly improves efficiency and safety over traditional methods of doing it track side.