Fast Response and Fully Capable

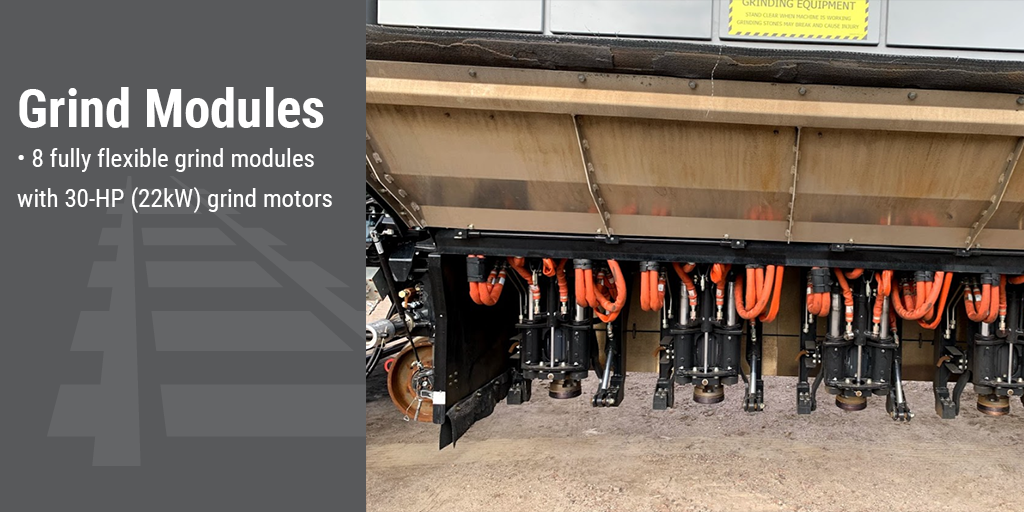

The Loram RGT Quick-Deploy Rail Grinder is a hi-rail equipped DOT certified 5th wheel rail grinder able to travel on virtually any North American roadway without any need for special permits. It features a fully-flexible rail grinding buggy with 8 stones, each powered by a 30 HP grinding motor to deliver the most finishing power and capabilities of any truck-mounted solution. Plus, Loram-developed and proven 6” and 10” diameter grinding stones are optimized for performance and life to achieve rail finishes from heavy metal removal to super smooth mirror finish –or any combination of both– in fewer passes. Designed to optimize short service windows, the RGT can deploy or be recovered in as few as 5 minutes at a rail access point near a service destination. Whether grinding switches, crossings, transit track, open rail or areas of general service or exception remediation, the RGT packs the rail grinding power and experience of Loram in the most flexible and transportable platform.