BallastSaver

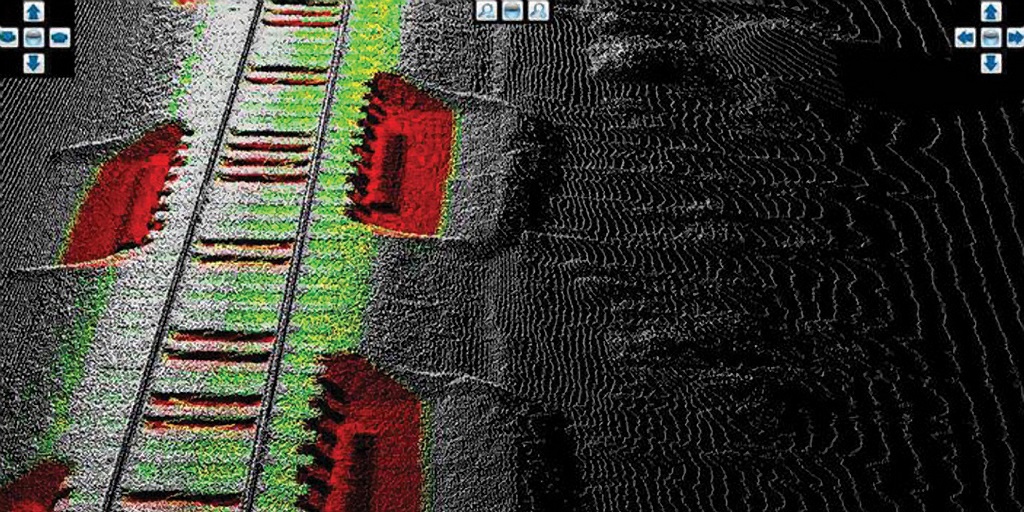

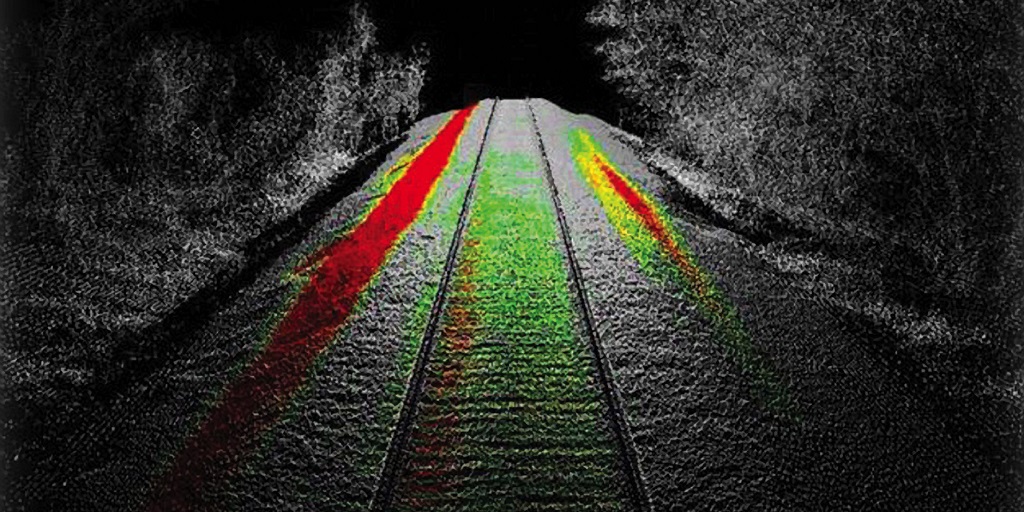

Take the guesswork out of determining your ballast needs with BallastSaver®. This pioneering technology enables you to deliver only the ballast you need right where it’s needed. Using advanced LiDAR, BallastSaver can analyse your existing ballast profile and compare it to an idealised profile, identifying any and all ballast deficiencies in the process.

By pinpointing your ballast needs, you can remove subjectivity from your ballast program. Now you can easily determine the number of ballast cars you need over a given area or prioritise the unloading of a car that’s already on site to dump ballast only in the most critical areas.

BallastSaver can work in tandem with our GateSync® system to automate the ballast delivery process. Automated delivery minimised the amount of ballast you need, reduces the manpower needed to get the job done, and avoids tying up your track longer than necessary.

BallastSaver can now be integrated onto the same hi-rail vehicle as our Aurora® track inspection system to provide a comprehensive view of the condition of your track in a single pass – from deficiencies in the ballast profile to flaws in your individual sleepers and rails. With the complete picture in front of you, you can plan out your capital maintenance programs with confidence.