History

1898

Loram’s parent company is launched, constructing railway grade on the Canadian Pacific Railroad.

1936

Seeing a growing need, Loram’s parent company diversifies into railway track maintenance. Up until then, most work of this kind was performed with simple hand tools and brute strength.

1955

The new Loram Plow is introduced.

1957

Loram receives its first double-track plow from the Calgary shops.

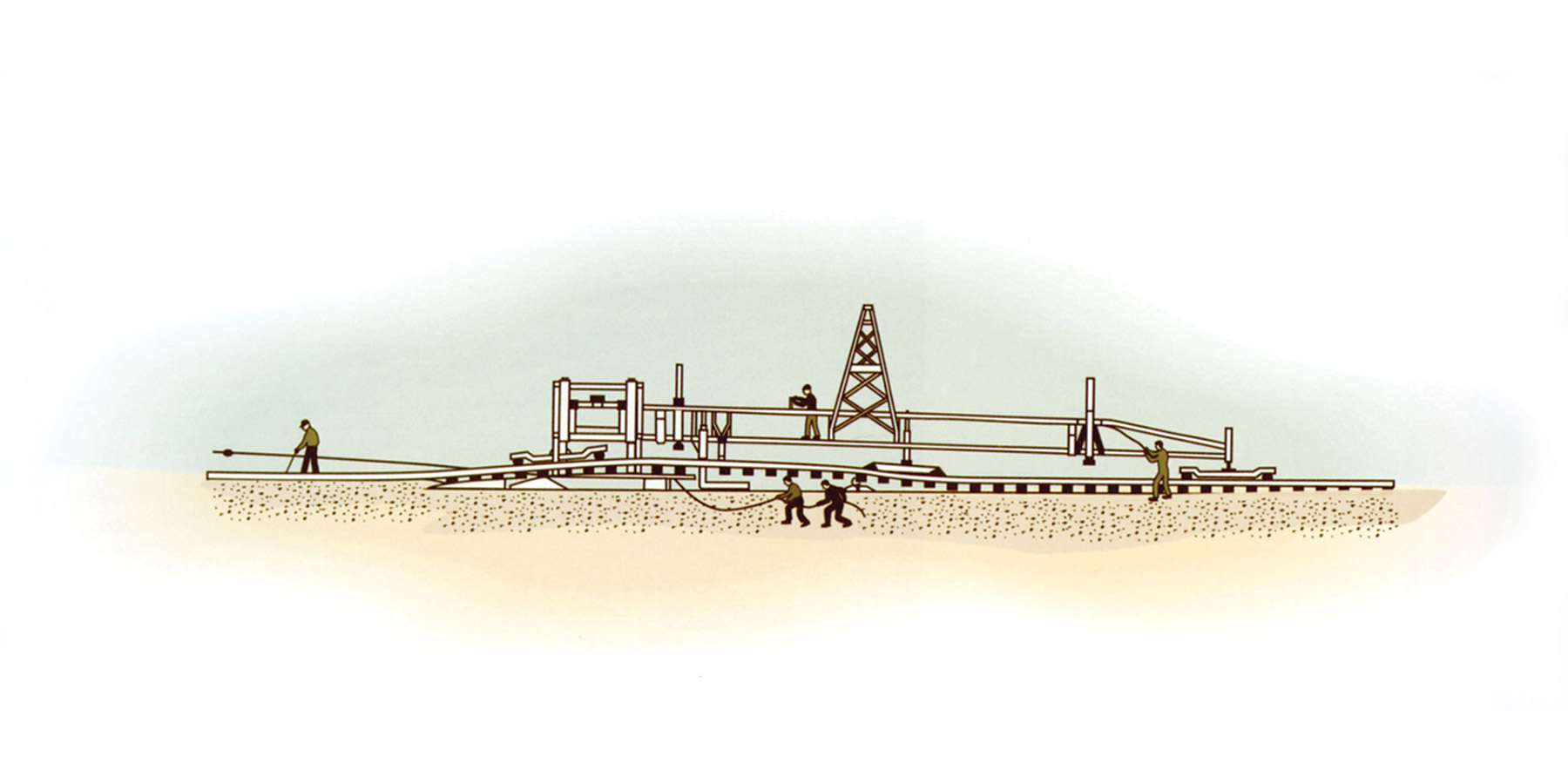

1958 & 1959

The Autotrack prototype is developed as a solution to maintain track alignment.

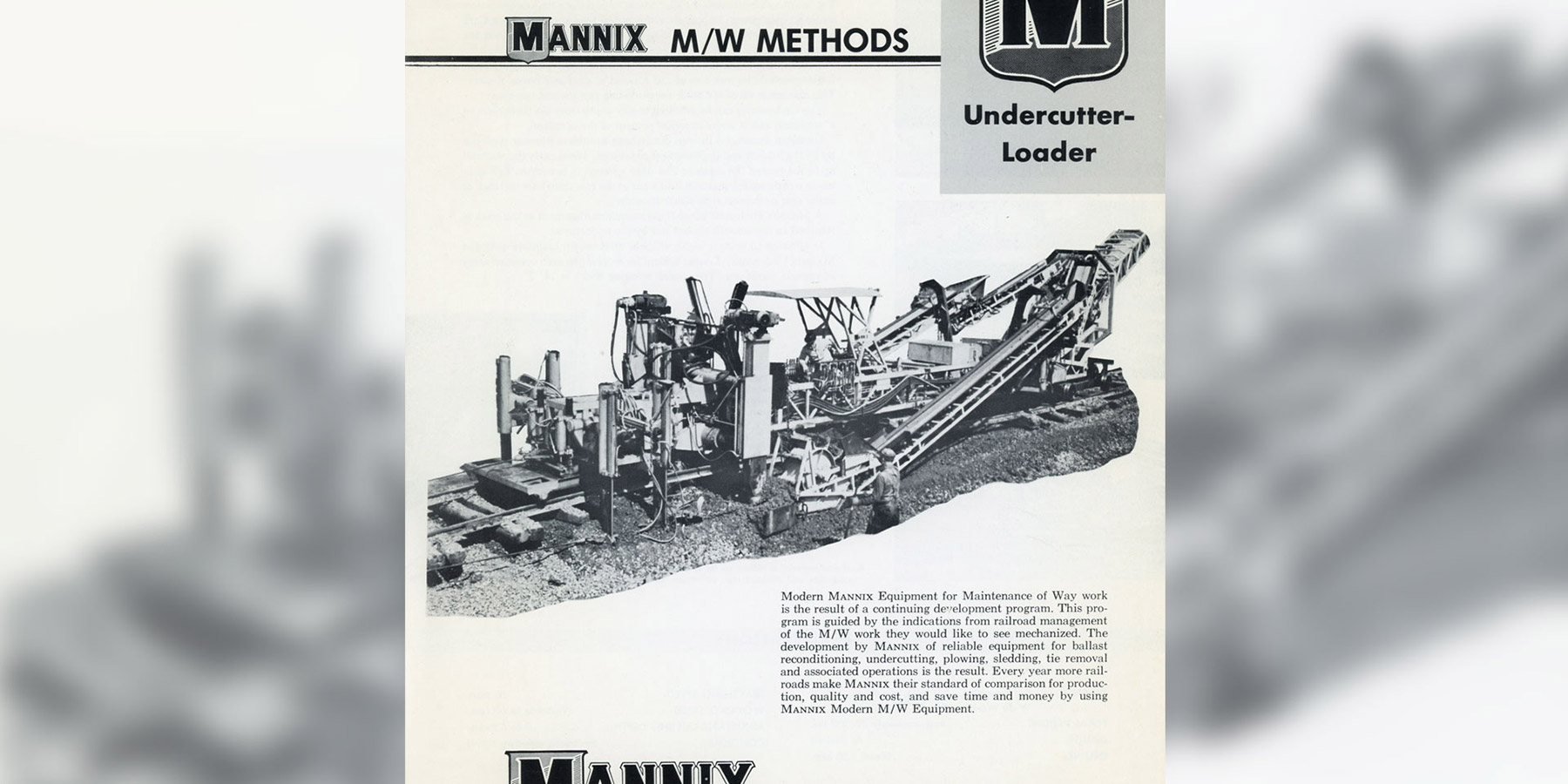

1960

The Loram Undercutter, a spin-off from the Autotrack and Sled designs, is developed. Its first job is lowering the track on the Stone Arch Bridge crossing the Mississippi River near Minneapolis, MN.

1962

The Loram Winch Cart prototype, made from junk yard parts, is developed to pull a sled, plow or Autotrack to eliminate the need for a work train.

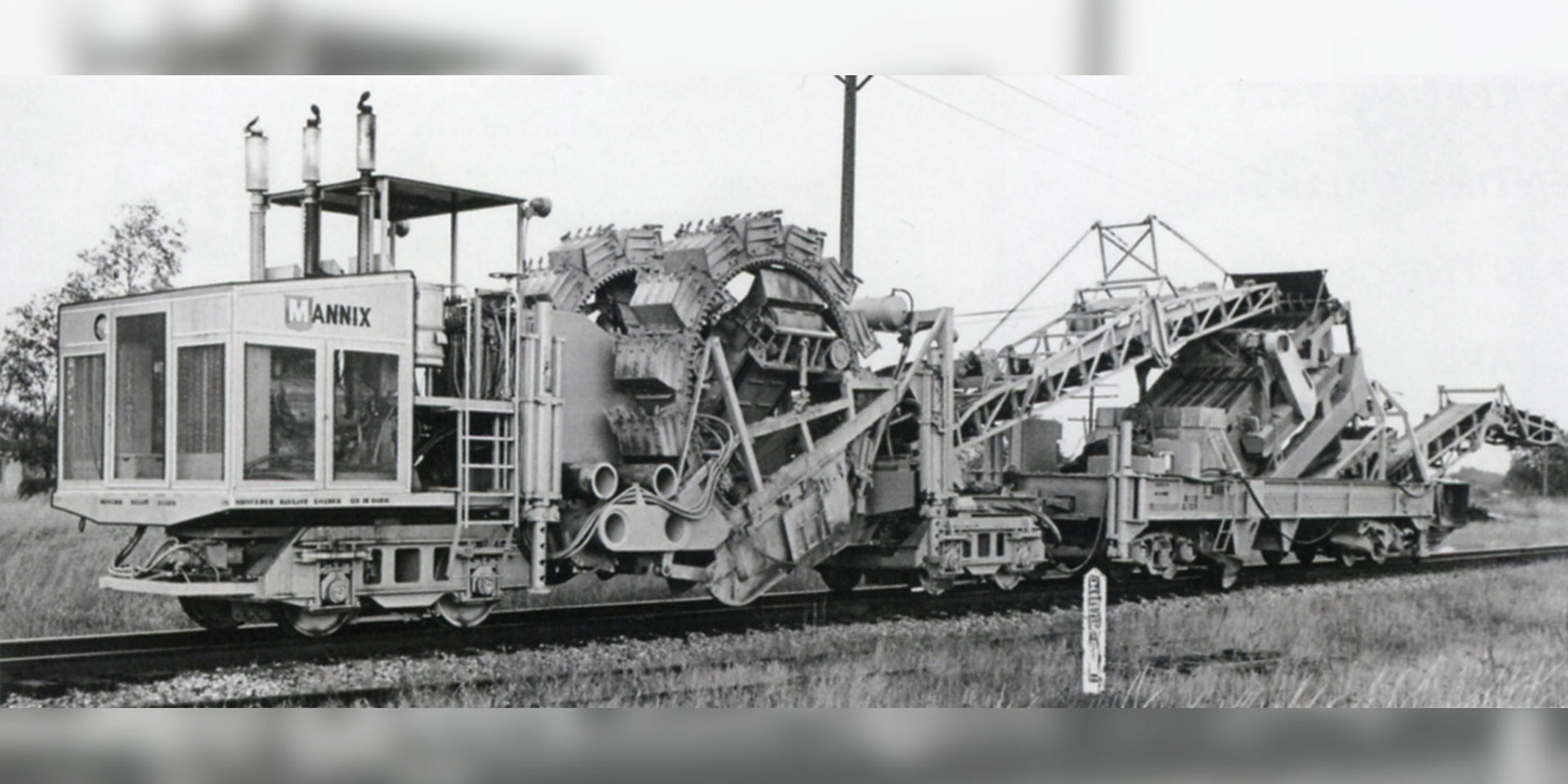

1963

Loram develops an Undercutter Cleaner, nicknamed “The Monster” with its many moving parts, which is Loram’s largest piece of equipment at 100 feet long, 14 feet high and 70 tons.

1968

Loram’s first Shoulder Ballast Cleaner is completed, one of Loram’s most successful pieces of equipment.

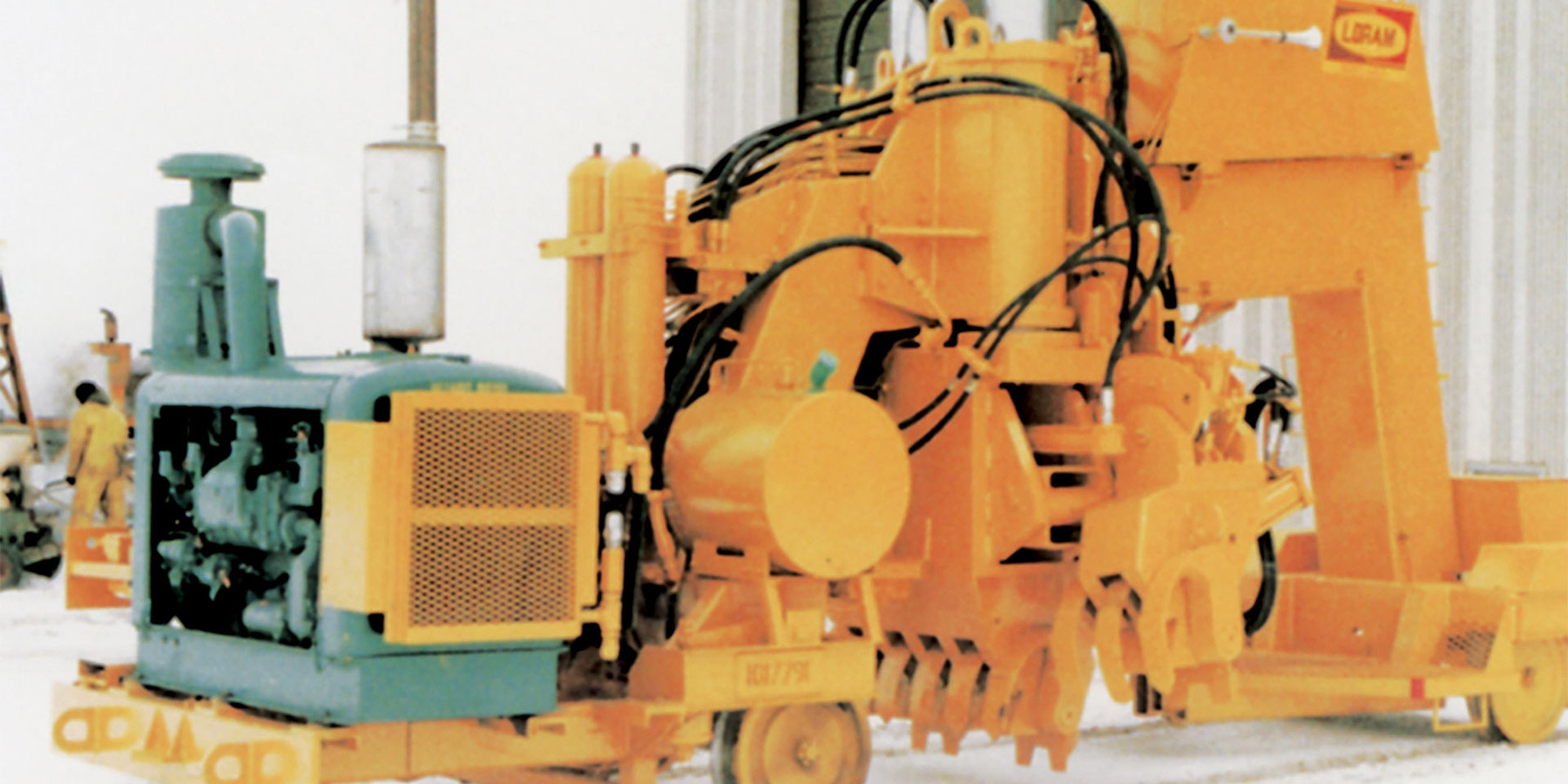

1969

Loram starts rail grinding research with Black & Decker hand grinders and is developed into a small self-propelled rail grinder that could handle spot-maintenance work.

1971

Loram’s first tie inserter is built.

1972

Loram introduces the Autosled.

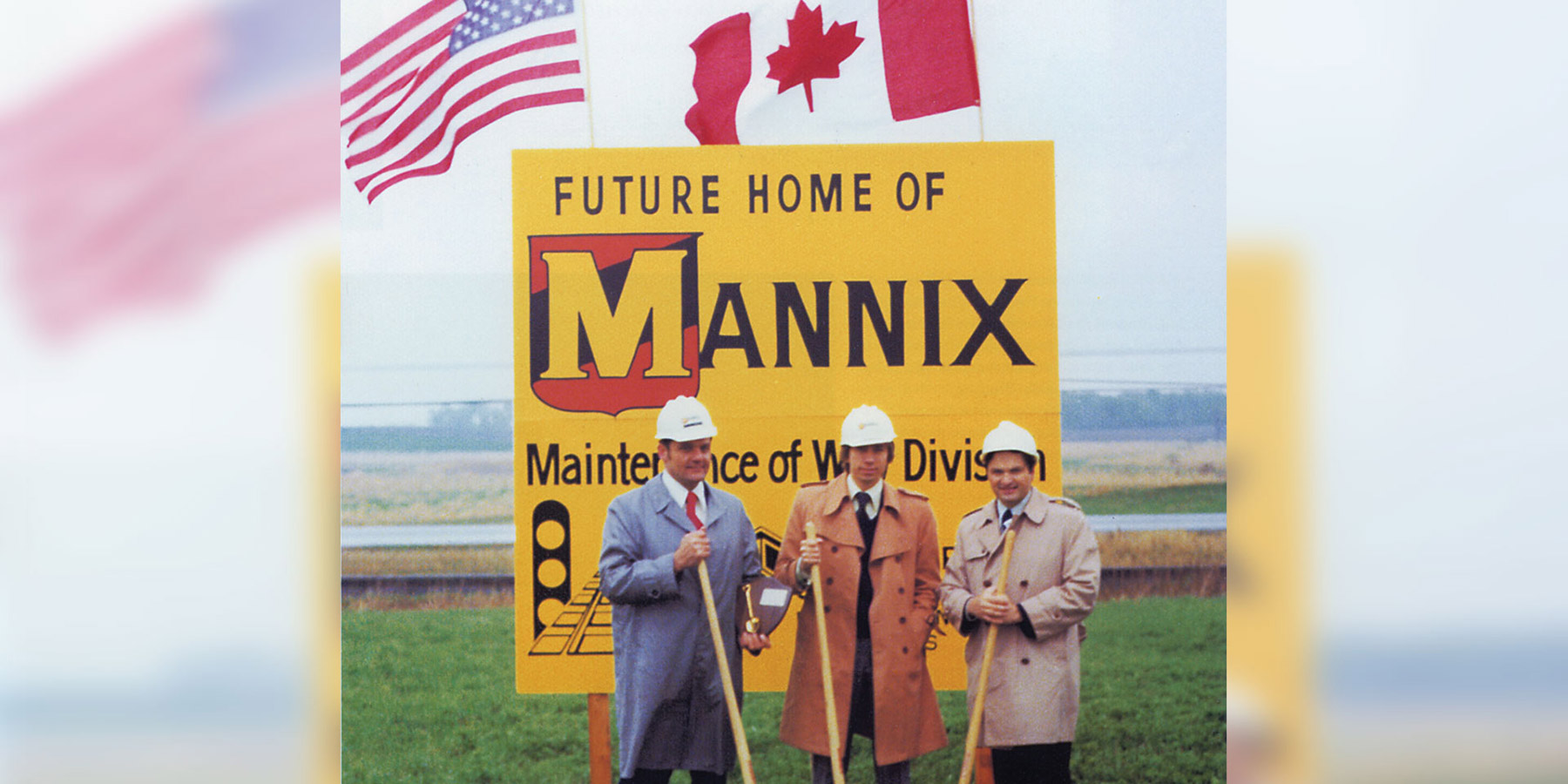

1974

Loram’s expansion leads to a new facility in Hamel, MN.

1979

Loram adds a tie extractor to the product line.

1983

Loram builds its first High Performance Shoulder Ballast Cleaners, SBC9 and SBC10.

1985

Loram builds RG8 and RG10, the first computer controlled rail grinders.

1985

Loram introduces its first Badger Ditch Cleaner.

1986

Loram’s first Switch and Crossing Rail Grinder is built.

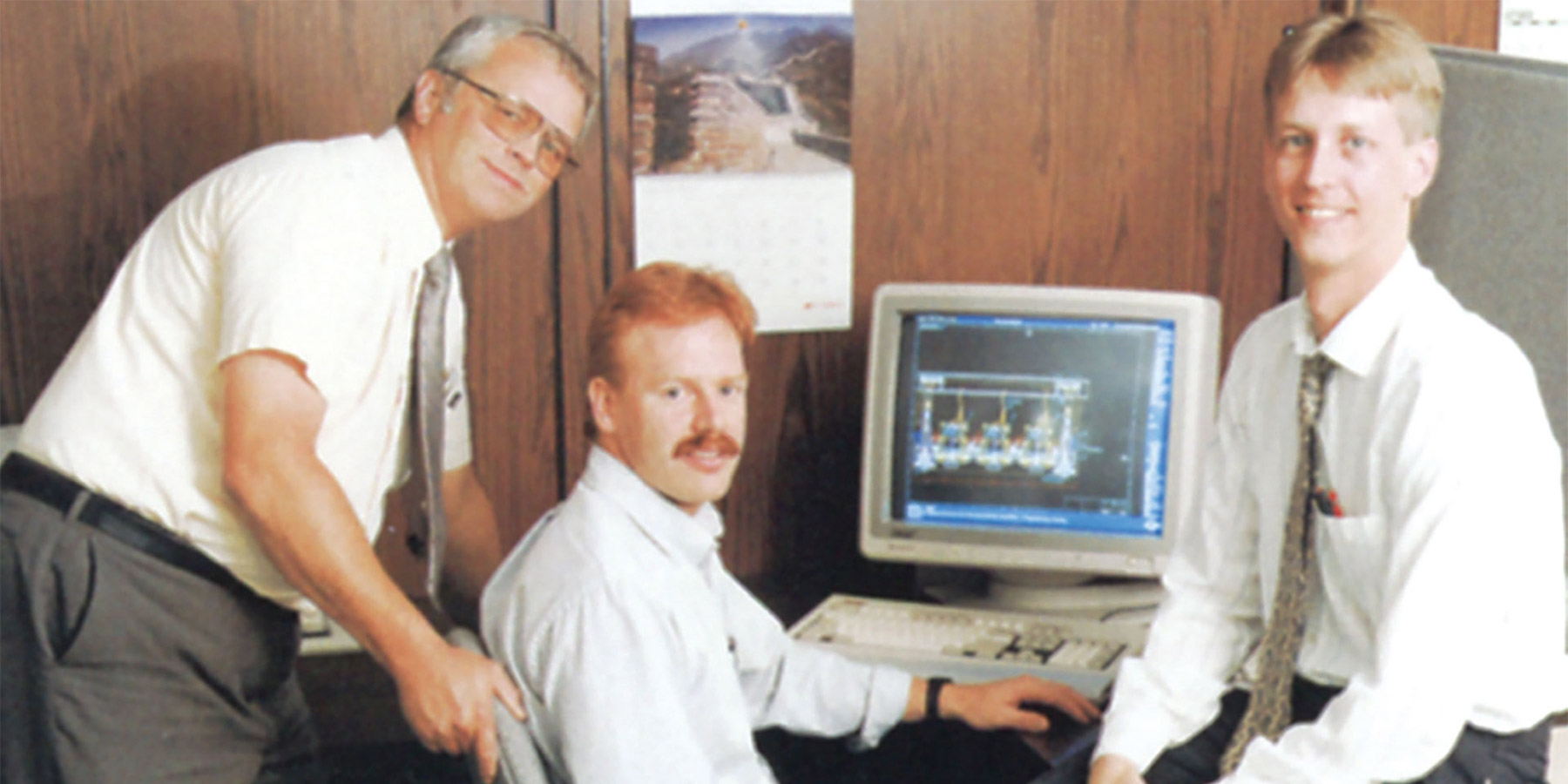

1990

Loram’s engineering department begins utilising CAD System Engineering.

1992

Loram acquires Rotra rail grinding technology for transit systems

1995

C2101 is built to new standards in safety, quality, performance and environmental protection.

1998

Loram’s parents company celebrates its 100th-year anniversary.

2001

Loram unveils its first two Railvacs, LRV1 and LRV2

2004

Loram celebrates its 50th Anniversary.

2004

Loram introduces MPC1.

2005

Loram develops and builds the Raptor Rail Train.

2009

Loram builds its first Transit Railvac.

2010

Loram develops the Track Lifter Undercutter.

2011

Loram acquires Tranergy, Inc., a leader in Friction Management.

2011

Loram implements ICARE Care Values.

2014

Loram celebrates 60 years.

2015

Loram doubles the performance of its Shoulder Ballast Cleaners with the inception of the SBC2400.

2016

Loram delivers three C44 rail grinders to Network Rail in the United Kingdom.

2016

Loram unveils the UC1200 undercutter cleaner.

2017

Loram acquires HyGround Engineering, experts in track in substructure maintenance and management.

2018

Loram acquires Georgetown Rail Equipment (GREX), an innovative railroad maintenance solution provider.